What To Know About 3D Printing in Healthcare?

Written by

Arterex Medical

Published on

August 26 , 2025

Read time

35 minute read

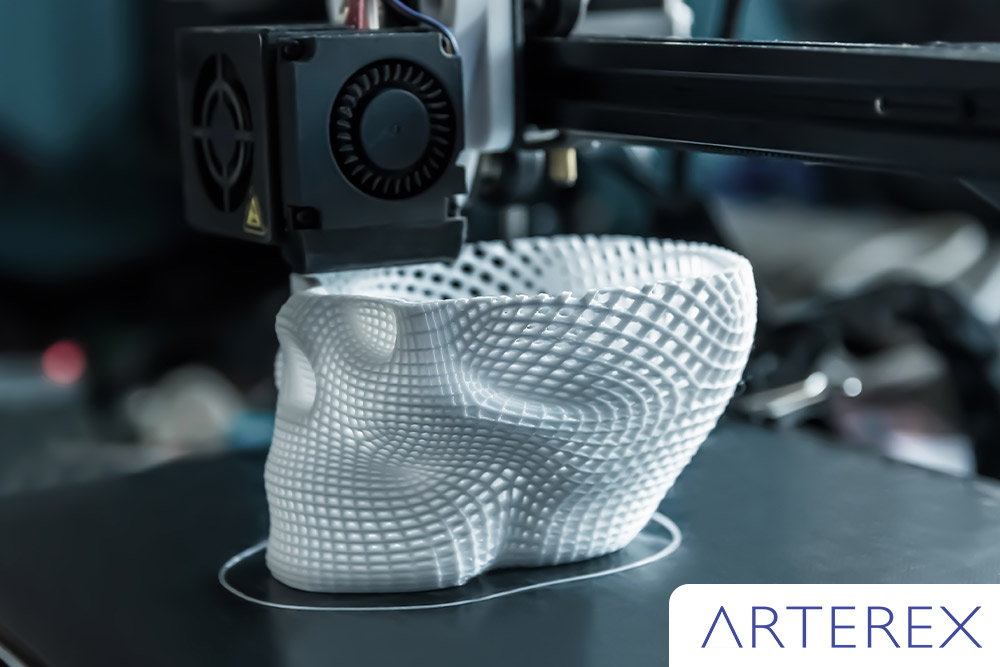

Medical 3D printing represents one of healthcare’s most transformative technological advances, fundamentally changing how medical professionals approach patient treatment and device manufacturing. This revolutionary additive manufacturing technology creates customized medical devices, implants, prosthetics, and anatomical models directly from digital medical data, enabling unprecedented personalization in patient care.

The technology transforms medical images from CT scans, MRIs, and X-rays into precise three-dimensional objects built layer by layer. This process enables healthcare providers to create exact anatomical replicas and patient-specific treatment solutions that were previously impossible through traditional manufacturing methods.

Medical 3D printing addresses fundamental healthcare challenges, particularly the limitations of one-size-fits-all devices that often fail to accommodate individual patient anatomy. Children can receive custom prosthetics for under $50 compared to traditional devices costing $15,000-$40,000. Surgeons practice complex procedures on exact patient replicas, reducing operation times and improving outcomes.

Applications span virtually every medical specialty, from surgical guides and dental restorations to permanent implants and experimental bioprinted tissues. Multiple printing technologies serve different needs: FDM for cost-effective surgical guides, SLA for precise dental work, and advanced bioprinting for tissue engineering using living cells.

The technology offers transformative advantages including personalized treatment, reduced surgery times, cost-effectiveness, and complex geometry creation impossible through traditional methods. However, challenges include regulatory complexity, quality control issues, limited materials, and technical expertise requirements.

Despite limitations, medical 3D printing continues advancing rapidly, driven by technological improvements and growing clinical evidence. As healthcare systems seek more efficient, personalized treatment options, this technology establishes the foundation for next-generation medical breakthroughs, making personalized healthcare accessible worldwide.

What is Medical 3D Printing?

Medical 3D printing is an advanced additive manufacturing technology that creates customized medical devices, implants, prosthetics, anatomical models, and even biological tissues directly from digital medical data. This revolutionary process transforms medical images from CT scans, MRIs, and X-rays into precise, three-dimensional objects built layer by layer, enabling accurate replication of complex structures and improving patient care.

What Are the Benefits of 3D Printing in Healthcare?

The benefits of 3D printing in healthcare are listed below:

3D printing allows fully customized medical devices tailored to a patient’s anatomy. Prosthetics, implants, and surgical guides can match exact measurements, improving fit, function, and patient comfort. Children can receive colorful, personalized prosthetics, boosting confidence and engagement.

3D printing lowers manufacturing costs and shortens production times. Prosthetics and surgical models that once took weeks and thousands of dollars can now be made in days at a fraction of the cost. Rapid production accelerates treatment and helps healthcare facilities serve more patients efficiently.

Surgeons can practice complex procedures using 3D anatomical models. Custom surgical guides improve implant placement, reduce surgery time, and enhance accuracy. These tools help minimize complications and shorten recovery times.

3D printing enables intricate designs impossible with traditional methods. Porous bone implants encourage natural integration, drug delivery devices can have precise internal channels, and prosthetics can combine multiple materials for better performance and lighter weight.

Design iterations are faster and cheaper, accelerating medical device development. Researchers can test multiple prototypes quickly, improve devices based on trial feedback, and achieve faster regulatory approvals.

Anatomical models help patients understand diagnoses and procedures, enhancing informed consent and treatment compliance. Seeing and touching a model reduces anxiety and makes explanations clearer than 2D images.

3D printing brings medical devices to remote or underserved regions. Local production reduces dependence on imports, makes healthcare more resilient in emergencies, and lowers costs for patients.

Hospitals can print devices on-demand, reducing inventory needs and waste. During crises, critical tools and protective equipment can be produced locally, bypassing supply chain disruptions.

Modern 3D printers achieve exceptional accuracy, with consistent, traceable quality. Digital manufacturing ensures reproducibility, supports regulatory compliance, and minimizes variability.

3D printing enables bioprinting, multi-material devices, and personalized treatments tailored to genetics and lifestyle. New approaches in tissue regeneration, drug delivery, and combination devices expand what’s possible in patient care.

What Are Examples of 3D Printing in Healthcare?

The examples of 3D Printing in healthcare are listed below:

1. Upper Limb Prosthetics

The e-NABLE community has produced over 3,000 3D printed prosthetic hands for children worldwide. These devices cost under $50 to produce compared to $15,000-$40,000 for traditional prosthetics. Children receive colorful, customizable hands featuring their favorite superheroes or sports teams.

Limbitless Solutions creates 3D printed bionic arms for children born with limb differences. Their Iron Man-inspired prosthetics use myoelectric sensors to detect muscle movements, allowing children to control multiple grip patterns. The lightweight design and custom fit improve comfort and functionality.

2. Cranio-Maxillofacial Reconstruction

A motorcycle accident victim received a 3D printed titanium jaw implant that restored both function and appearance. The custom implant, designed from CT scan data, allowed the patient to eat, speak, and smile normally after the accident destroyed most of his lower jaw.

Skull reconstruction cases frequently use 3D printed titanium or PEEK implants. Patients with head trauma or brain tumors receive custom skull plates that match their original bone contours, providing protection and aesthetic restoration.

Why is 3D Printing Important in Healthcare?

3D printing is transforming healthcare by enabling personalized treatment, improving patient outcomes, and accelerating medical innovation.

1. Addressing Core Challenges

Traditional medical devices often use one-size-fits-all designs that may not fit individual anatomy, causing discomfort, poor function, or complications. 3D printing allows fully customized devices, implants, and prosthetics, eliminating these mismatches. It also reduces manufacturing costs, shortens production times, and decreases dependence on complex supply chains.

2. Enhancing Patient Outcomes

Custom devices improve comfort, treatment success, and compliance. Surgeons can plan and practice complex procedures with anatomical models, reducing complications and shortening recovery times. Pediatric patients and those with rare conditions benefit from devices tailored to their unique needs.

3. Accelerating Innovation

Rapid prototyping allows researchers to design, test, and refine medical devices faster. Multi-material, complex, and biologically integrated devices are now possible, enabling treatments that traditional manufacturing could not support.

4. Improving Surgical and Medical Education

3D printed anatomical models enhance training for medical students, residents, and practicing physicians. Surgeons rehearse complex operations, and patients better understand their conditions, leading to more informed decisions.

5. Supporting Sustainability and Accessibility

On-demand printing reduces waste, minimizes storage needs, and lowers costs. Remote and underserved regions gain access to advanced medical devices without relying on long supply chains. Emergency situations and pandemics benefit from locally produced medical tools.

6. Preparing for Future Healthcare Needs

3D printing supports aging populations, pandemic preparedness, and extreme-environment medicine. Its convergence with AI, robotics, and biotechnology promises even greater healthcare transformation.

In short, 3D printing is critical for personalized, precise, sustainable, and accessible healthcare, laying the foundation for the next generation of medical breakthroughs.

How Does Medical 3D Printing Work?

Medical 3D printing transforms digital medical images into precise, three-dimensional objects that improve patient care, enable personalized treatments, and support surgical planning. This technology builds objects layer by layer using specialized materials designed for medical applications, including prosthetics, implants, anatomical models, and experimental bioprinted tissues.

1. Digital Foundation: From Medical Images to 3D Models

The process begins with medical imaging data from CT scans, MRI scans, X-rays, or ultrasounds. These scans capture detailed internal anatomy, creating the basis for a patient-specific digital model. Radiologists and biomedical engineers process thousands of image slices using specialized 3D modeling software, reconstructing a complete, accurate representation of the anatomy.

The digital model serves as a blueprint for the physical object, allowing adjustments for size, shape, flexibility, and internal structures. Engineers optimize the design for functionality, fit, and clinical requirements.

2. Slicing and Printing Instructions

Once the 3D model is finalized, the software slices it into hundreds or thousands of thin layers, typically 0.1–0.3 millimeters thick. Each layer corresponds to a cross-section of the final object. The printer receives these instructions and builds the object from the bottom up, layer by layer.

Depending on the printing technology:

- Stereolithography (SLA) uses UV light to cure liquid resin.

- Selective Laser Sintering (SLS) fuses powdered materials using a laser.

- Fused Deposition Modeling (FDM) extrudes heated filament to form layers.

- Bioprinting deposits living cells to create tissue structures.

Support structures may be printed alongside the main object to prevent deformation during the process. Print times vary: simple surgical guides may take a few hours, while complex anatomical models can require 12 hours or more.

3. Medical-Grade Materials

Medical 3D printing uses biocompatible materials appropriate for human use. Common options include:

- Plastics (PLA, ABS) for prosthetics and surgical guides

- Titanium and metal alloys for implants

- Ceramics for bone scaffolds

- Bioinks containing living cells for tissue engineering

Material selection depends on the device’s purpose, required strength, and biocompatibility.

4. Post-Processing, Quality Control, and Sterilization

After printing, objects undergo post-processing to enhance mechanical properties and surface finish. Steps may include curing, sintering, polishing, or coating. Rigorous quality control ensures dimensional accuracy, material integrity, and adherence to medical standards.

Sterilization removes contaminants, typically through steam, gamma radiation, or ethylene oxide gas, depending on the material. This ensures devices are safe for clinical use.

5. Future Possibilities

The future of medical 3D printing includes bioprinting functional tissues and organs, smart implants with embedded sensors, and drug-eluting devices that release medication at controlled rates. Advances in materials and printing precision will make personalized medicine more accessible, effective, and transformative worldwide.

What Are 3D Printing Technologies Used in Healthcare?

Healthcare professionals use several distinct 3D printing technologies, each with unique advantages for specific medical applications. Understanding these technologies helps medical teams choose the right printing method for their particular needs.

1. Fused Deposition Modeling (FDM)

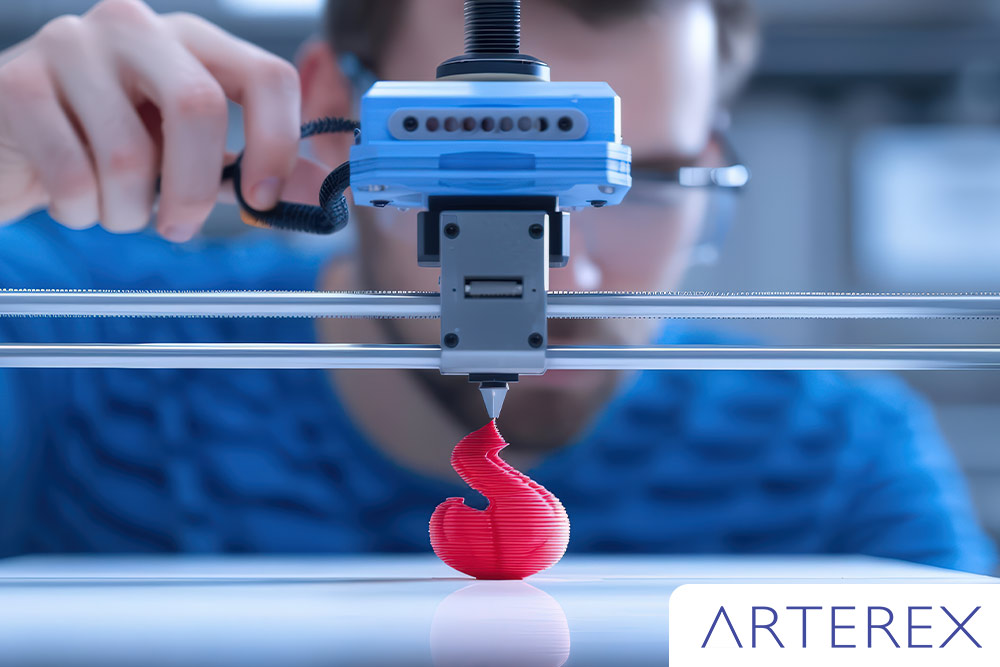

FDM printers heat plastic filaments until they become molten, then extrude the material through a heated nozzle. The nozzle moves in precise patterns, depositing layers of plastic that cool and solidify immediately upon contact.

Medical teams frequently use FDM for creating surgical guides, anatomical models, and prosthetic prototypes. The technology works well with biocompatible plastics like PLA and PETG, making it suitable for devices that contact human tissue.

FDM offers excellent cost-effectiveness and reliability for most medical modeling applications. Print times are reasonable, and the technology requires minimal specialized training to operate safely.

2. Stereolithography (SLA)

SLA technology uses ultraviolet lasers to cure liquid photopolymer resins into solid plastic. The laser selectively hardens resin according to each layer’s digital pattern, creating highly detailed objects with smooth surface finishes.

Dental applications particularly benefit from SLA’s precision capabilities. Dentists print crowns, bridges, and surgical guides with accuracy levels that rival traditional manufacturing methods.

The technology produces superior surface quality compared to FDM, making it ideal for patient-facing devices and detailed anatomical models. However, the liquid resins require careful handling and proper ventilation during printing.

3. Selective Laser Sintering (SLS)

SLS printers use powerful lasers to fuse powdered materials into solid objects. The laser selectively melts powder particles according to each layer’s specifications, creating strong, durable parts without requiring support structures.

Medical device manufacturers rely on SLS for creating functional implants and surgical instruments. The technology works with various materials including nylon, titanium, and specialized medical-grade powders.

SLS produces parts with excellent mechanical properties that can withstand sterilization procedures. The powder bed acts as natural support material, allowing complex geometries that would be impossible with other technologies.

4. Electron Beam Melting (EBM)

EBM technology uses focused electron beams to melt metal powders in a vacuum environment. The electron beam selectively fuses titanium and other metal powders to create fully dense, biocompatible implants.

Orthopedic surgeons use EBM-printed titanium implants for hip replacements, spinal hardware, and skull reconstruction. The porous structures printed with EBM encourage natural bone growth and integration.

The vacuum environment prevents oxidation during printing, resulting in chemically pure implants with excellent biocompatibility. EBM produces implants with mechanical properties that match or exceed traditionally manufactured alternatives.

5. Digital Light Processing (DLP)

DLP printers cure entire layers simultaneously using digital light projectors. This approach significantly reduces print times compared to laser-based systems that trace each layer point by point.

Dental laboratories use DLP technology for high-volume production of crowns, dentures, and orthodontic models. The simultaneous layer curing enables batch production of multiple parts during single print runs.

The technology offers excellent detail resolution and surface finish quality. DLP systems require less maintenance than laser-based alternatives and provide consistent results across large print volumes.

6. Binder Jetting

Binder jetting technology selectively deposits liquid binding agent onto powder beds to form solid objects. The process builds parts layer by layer without requiring heat or lasers during the printing phase.

Medical researchers use binder jetting for creating pharmaceutical tablets with controlled drug release profiles. The technology can incorporate multiple active ingredients into single dosage forms with precise distribution patterns.

The process works with various powder materials including metals, ceramics, and pharmaceutical compounds. Post-processing steps like sintering or infiltration may be required to achieve final material properties.

7. Bioprinting Technologies

Bioprinting represents the most advanced application of 3D printing in healthcare. These specialized systems deposit living cells, growth factors, and biomaterials to create functional tissue constructs.

Inkjet-based bioprinters work similarly to desktop inkjet printers but use bioinks containing living cells instead of traditional inks. Extrusion-based bioprinters push cell-laden hydrogels through small nozzles to build tissue structures.

Researchers have successfully bioprinted skin grafts, cartilage, and simple organ structures in laboratory settings. While still largely experimental, bioprinting holds tremendous promise for regenerative medicine applications.

8. Multi-Material Printing

Advanced medical 3D printers can combine multiple materials within single objects. These systems switch between different materials during printing to create parts with varying mechanical, chemical, or biological properties.

Multi-material printing enables creation of surgical models that accurately replicate the different tissue densities found in human anatomy. Surgeons can practice on models that feel and respond like actual patient tissue.

The technology also allows printing of drug-eluting devices with controlled release mechanisms built directly into the device structure. This capability opens new possibilities for personalized medication delivery systems.

How To Choose the Right Technology for 3D Printing?

Selecting the right 3D printing technology depends on the specific medical application, the required material, and the level of precision needed. Each technology has strengths and limitations, making it important to match the method with the intended outcome.

1. Material Requirements

The choice of material often dictates the best technology.

- FDM (Fused Deposition Modeling) and SLA (Stereolithography): Ideal for biocompatible plastics used in surgical guides, prosthetics, and anatomical models.

- SLS (Selective Laser Sintering) and EBM (Electron Beam Melting): Required for metal implants, such as titanium orthopedic and dental devices.

2. Precision and Accuracy

Applications that demand high levels of accuracy benefit from different systems.

- SLA and DLP (Digital Light Processing): Provide exceptional detail, making them well-suited for dental restorations, crowns, and orthodontic devices.

- FDM: Offers sufficient accuracy for surgical planning models where perfect precision is less critical.

3. Production Volume

The expected production scale also plays a role in technology selection.

- DLP: Efficient for batch production, especially when producing multiple dental or medical parts simultaneously.

- FDM: Flexible and cost-effective for one-off prototypes, personalized devices, and custom surgical models.

By weighing material compatibility, precision needs, and production volume, healthcare providers and engineers can identify the 3D printing technology that delivers the best clinical and economic outcomes.

What Are Materials Used in 3D Printing?

Medical 3D printing relies on specialized materials designed to meet strict biocompatibility and safety standards. These materials must perform reliably in contact with human tissue while maintaining their structural integrity under physiological conditions.

- Biocompatible Plastics form the foundation of medical 3D printing materials. PLA (Polylactic Acid) offers excellent printability and biodegradability, making it suitable for temporary implants and surgical guides. ABS (Acrylonitrile Butadiene Styrene) provides superior strength and chemical resistance for durable medical devices.

PEEK (Polyetheretherketone) represents the gold standard for high-performance medical plastics. This material matches bone stiffness closely and resists degradation in body fluids, making it ideal for spinal implants and orthopedic applications.

- Medical-Grade Metals enable printing of permanent implants with exceptional strength and longevity. Titanium alloys dominate orthopedic applications due to their excellent biocompatibility and ability to integrate with natural bone tissue.

Stainless steel serves specialized applications requiring magnetic compatibility or cost-effectiveness. Cobalt-chromium alloys offer superior wear resistance for joint replacement components that experience high mechanical stress.

- Photopolymer Resins provide exceptional detail resolution for dental and surgical applications. BioMed Clear resin allows creation of transparent surgical guides that don’t obstruct the surgeon’s view during procedures.

Dental-specific resins include materials optimized for crowns, bridges, and orthodontic appliances. These resins cure to match natural tooth color and provide appropriate hardness for chewing forces.

- Bioinks and Living Materials represent the cutting edge of medical printing technology. Hydrogel-based bioinks suspend living cells in printable matrices that support cell growth and tissue formation.

Collagen-based bioinks mimic natural extracellular matrix components, providing familiar environments for cell attachment and proliferation. Alginate bioinks offer excellent printability while maintaining cell viability throughout the printing process.

- Ceramic Materials serve specialized applications requiring exceptional hardness and chemical inertness. Hydroxyapatite ceramics match natural bone mineral composition, promoting excellent integration with existing bone tissue.

Zirconia ceramics provide tooth-colored dental restorations with superior strength and stain resistance compared to traditional porcelain alternatives.

What Are The Applications of 3D Printing in Healthcare?

Medical 3D printing applications span virtually every medical specialty, transforming how healthcare professionals diagnose, treat, and care for patients.

- Surgical Planning and Training represents one of the most established applications. Surgeons print patient-specific anatomical models from CT or MRI data, allowing detailed examination of complex anatomy before entering the operating room.

These models enable surgical teams to identify potential complications, select optimal surgical approaches, and reduce operation times. Medical students and residents use printed models for hands-on training without risking patient safety.

- Custom Prosthetics and Orthotics provide perfectly fitted devices tailored to individual patient anatomy. Traditional prosthetic fitting requires multiple appointments and adjustments, while 3D-printed devices can be designed from precise body scans.

Pediatric patients particularly benefit from rapid prosthetic replacement as they outgrow devices. Parents can simply request new prints as children develop, eliminating lengthy manufacturing delays.

- Dental Applications have revolutionized modern dentistry through same-day treatment capabilities. Dentists scan patients’ mouths and print crowns, bridges, and night guards while patients wait.

Orthodontic treatment uses a series of 3D-printed aligners to gradually move teeth into proper position. Each aligner is custom-designed for specific stages of treatment, providing precise tooth movement control.

- Pharmaceutical Applications enable creation of personalized medications with controlled release profiles. Pharmacists can print tablets containing multiple active ingredients with precisely controlled dosing and timing.

This capability particularly benefits pediatric and geriatric patients who require modified dosing regimens or have difficulty swallowing standard tablets.

- Medical Device Manufacturing produces specialized instruments and implants that would be impossible to create through traditional manufacturing methods.

Custom surgical guides ensure accurate placement of screws, pins, and other hardware during orthopedic procedures. Patient-specific cutting guides help surgeons make precise bone cuts during joint replacement surgeries.

- Tissue Engineering Research explores printing functional tissue constructs that could eventually replace damaged organs. Researchers have successfully printed skin grafts, cartilage patches, and simple organ structures in laboratory settings.

While still largely experimental, these applications hold tremendous promise for treating conditions that currently require organ transplantation.

What Organs Are 3D Printed in Healthcare?

Current organ printing capabilities focus primarily on simple tissues and organ components rather than complete, transplantable organs. However, significant progress continues across multiple organ systems.

- Skin Tissue represents the most clinically advanced application of organ printing. Researchers have successfully printed skin grafts containing multiple cell types arranged in natural skin architecture.

These printed skin grafts show promise for treating severe burns and chronic wounds. The grafts can be customized to match patient skin color and thickness, potentially eliminating rejection issues associated with donor tissue.

- Cartilage Structures benefit from 3D printing’s ability to create complex internal architectures. Printed cartilage constructs contain living cells embedded in supporting scaffolds that gradually dissolve as natural cartilage forms.

Ear reconstruction represents a particularly successful application, with printed ear cartilage frameworks providing structural support for cosmetic reconstruction procedures.

- Blood Vessels and Vascular Networks address one of the most challenging aspects of organ printing. Functional organs require intricate blood vessel networks to supply nutrients and remove waste products.

Researchers have printed simple blood vessel tubes and are working toward creating branching vascular networks that could support larger tissue constructs.

- Bone and Joint Components utilize the excellent biocompatibility of printed titanium and ceramic materials. Printed bone scaffolds encourage natural bone growth while providing immediate structural support.

Custom joint components can be designed to match patient anatomy precisely, potentially improving implant longevity and reducing revision surgery rates.

- Heart Tissue Components focus on printing cardiac patches and valve components rather than complete hearts. Printed heart patches could repair damaged heart muscle following heart attacks.

Researchers have created beating heart tissue in laboratory settings, demonstrating that printed cardiac cells can maintain synchronized contractions necessary for heart function.

- Liver Tissue Models serve primarily as research tools for drug testing and disease modeling. While complete liver printing remains distant, printed liver tissue constructs can perform many liver functions in laboratory settings.

These models help pharmaceutical companies test drug safety and effectiveness before human trials, potentially reducing development costs and improving drug safety.

What Are The Advantages of 3D Printing in Healthcare?

Medical 3D printing offers transformative advantages that address longstanding challenges in healthcare delivery and patient outcomes.

- Personalized Treatment stands as perhaps the greatest advantage of medical 3D printing. Every patient possesses unique anatomy, and 3D printing enables creation of devices and treatments tailored to individual needs.

Custom implants fit better, last longer, and integrate more successfully with existing tissue compared to standard-sized alternatives. This personalization reduces complications and improves patient satisfaction significantly.

- Reduced Surgery Time results from improved surgical planning and custom-fitted devices. Surgeons who practice on patient-specific models can complete procedures more quickly and with greater confidence.

Shorter operations reduce anesthesia exposure, infection risk, and overall healthcare costs. Patients experience faster recovery times and return to normal activities sooner.

- Cost-Effectiveness emerges through reduced material waste and eliminated tooling requirements. Traditional manufacturing requires expensive molds and tooling for custom devices, while 3D printing builds objects directly from digital files.

Small production runs become economically viable, enabling custom devices for rare conditions that wouldn’t justify traditional manufacturing investments.

- Rapid Prototyping Capabilities accelerate medical device development from years to months. Engineers can quickly test multiple design iterations and incorporate feedback from surgeons and patients.

This rapid development cycle brings innovative treatments to patients faster while reducing overall development costs for medical device manufacturers.

- Complex Geometry Creation enables internal structures and geometries impossible to achieve through traditional manufacturing methods. Printed implants can incorporate porous structures that encourage bone growth and integration.

Hollow internal channels can deliver medications directly to treatment sites, while complex surface textures can improve device performance and biocompatibility.

- On-Demand Manufacturing eliminates inventory requirements and reduces supply chain vulnerabilities. Hospitals can print devices when needed rather than maintaining expensive inventories of rarely used items.

This capability proves particularly valuable in emergency situations or remote locations where traditional supply chains may be unreliable.

What Are The Disadvantages of 3D Printing in Healthcare?

Despite significant advantages, medical 3D printing faces important limitations and challenges that affect widespread adoption.

- Regulatory Complexity creates significant barriers to clinical implementation. Medical devices require extensive testing and regulatory approval before clinical use, and 3D-printed devices face additional scrutiny regarding manufacturing consistency.

The FDA and other regulatory bodies are still developing frameworks for evaluating 3D-printed medical devices, creating uncertainty for manufacturers and healthcare providers.

- Quality Control Challenges arise from the layer-by-layer manufacturing process inherent to 3D printing. Each layer represents a potential weak point where delamination or defects could occur.

Traditional manufacturing processes often provide more consistent material properties and structural integrity compared to 3D-printed alternatives. Medical applications demand extremely high reliability standards that can be difficult to achieve consistently.

- Limited Material Options restrict applications compared to traditional manufacturing methods. While the range of printable materials continues expanding, many specialized medical materials cannot yet be processed through 3D printing technologies.

Biocompatible materials suitable for 3D printing often cost significantly more than traditional alternatives, affecting the overall economic advantages of the technology.

- Speed Limitations become problematic for emergency applications or high-volume production requirements. Complex medical devices may require many hours or even days to print completely.

This time requirement conflicts with urgent medical needs and makes 3D printing unsuitable for applications requiring immediate device availability.

- Technical Expertise Requirements create barriers to widespread adoption in healthcare settings. Operating 3D printers safely and effectively requires specialized training that many healthcare professionals lack.

Design software, material handling, and post-processing procedures require technical knowledge that may be outside the typical scope of medical practice.

- Intellectual Property Concerns complicate the sharing of device designs and manufacturing processes. Digital design files can be easily copied and distributed, potentially undermining traditional business models for medical device companies.

Healthcare institutions must carefully manage digital design files to prevent unauthorized reproduction while ensuring appropriate access for legitimate medical applications.

- Sterilization Challenges affect certain 3D-printed materials and geometries. Complex internal structures may be difficult to clean and sterilize effectively, potentially creating infection risks.

Some printing materials may degrade during standard sterilization procedures, limiting their applicability for devices that require repeated sterilization cycles.

- What To Know About 3D Printing in Healthcare?

- What is Medical 3D Printing?

- How Does Medical 3D Printing Work?

- What Are 3D Printing Technologies Used in Healthcare?

- What Are Materials Used in 3D Printing?

- What Are The Applications of 3D Printing in Healthcare?

- What Are The Advantages of 3D Printing in Healthcare?